地圖 - 熱線

地圖 - 熱線

地圖 - 熱線

地圖 - 熱線

公司動態(tài)

- 服務熱線 - 15392885678 15069779222

技術概況:采用沸石轉輪吸附濃縮法對低濃度、大風量工業(yè)廢氣中的VOCs進行濃縮,對濃縮后的高濃度、小風量的污染空氣采用RTO蓄熱式氧化法進行分解凈化。

Technical Overview: The zeolite rotary adsorption concentration method is used to concentrate VOCs in low concentration and high air volume industrial waste gas. The concentrated high concentration and low air volume polluted air is decomposed and purified using RTO thermal storage oxidation method.

沸石轉輪+rto該技術的基本構思是:

The basic concept of zeolite wheel+RTO technology is:

含有VOCs 的污染空氣由鼓風機送到沸石轉輪的吸附區(qū),污染空氣在通過沸石轉輪蜂窩狀通道時,所含VOCs成分被吸附劑所吸附,空氣得到凈化。

Polluted air containing VOCs is sent by a blower to the adsorption area of the zeolite wheel. When the polluted air passes through the honeycomb channel of the zeolite wheel, the VOCs content is adsorbed by the adsorbent, and the air is purified.

隨著吸附轉輪的回轉,接近吸附飽和狀態(tài)的吸附轉輪進入到再生區(qū),在與180℃ -220 ℃高溫脫附再生空氣接觸的過程中,VOCs被脫附下來進入到再生空氣中,沸石轉輪得到再生。

As the adsorption wheel rotates, the adsorption wheel approaching saturation enters the regeneration zone. During the process of contact with the high-temperature desorption regeneration air at 180 ℃ -220 ℃, VOCs are desorbed and enter the regeneration air, and the zeolite wheel is regenerated.

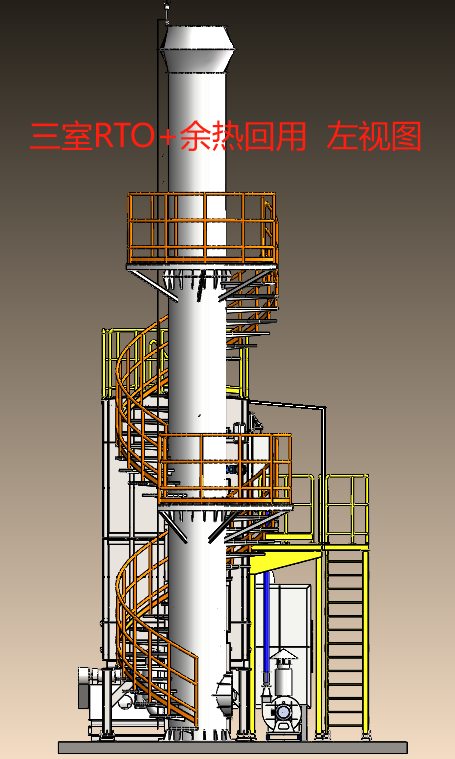

脫附后把大風量低濃度的有機廢氣濃縮成小風量高濃度的廢氣,再進入RTO蓄熱式氧化爐設備,經(jīng)過蓄熱室升溫吸熱,離開蓄熱室,進入氧化室,升到 800多 ℃的溫度,焚燒氧化廢氣,使廢氣氧化分解成二氧化碳和水。釋放的熱量可回收到設備內(nèi)循環(huán)使用,節(jié)能環(huán)保,節(jié)省能耗損失。

After desorption, the high air volume and low concentration organic waste gas is concentrated into low air volume and high concentration waste gas, which then enters the RTO thermal storage oxidation furnace equipment. After being heated and absorbed by the heat storage chamber, it leaves the storage chamber and enters the oxidation chamber, rising to a temperature of over 800 ℃. The oxidized waste gas is incinerated to oxidize and decompose into carbon dioxide and water. The heat released can be recycled and reused within the equipment, which is energy-saving, environmentally friendly, and saves energy losses.

工藝特點:

Process characteristics:

1、RTO系統(tǒng)采用PLC自動燃燒控制,全自動化控制、運行穩(wěn)定.

1. The RTO system adopts PLC automatic combustion control, fully automated control, and stable operation

2、濃縮倍數(shù)達到5-20倍,使原本大風量、低濃度的VOCs廢氣,轉換成低風量、高濃度的廢氣,大大縮小后處理設備的規(guī)格,運行成本低

2. The concentration factor reaches 5-20 times, converting the originally high air volume and low concentration VOCs waste gas into low air volume and high concentration waste gas, greatly reducing the specifications of post-treatment equipment and reducing operating costs

3、沸石轉輪吸附VOCs所產(chǎn)生的壓降極低,可大大減少電力能耗

3. The pressure drop generated by zeolite wheel adsorption of VOCs is extremely low, which can greatly reduce power consumption

設備應用:涂裝廢氣、印刷廢氣、化工廢氣、覆銅板廢氣等工業(yè)廢氣源。

Equipment application: Industrial waste gas sources such as coating waste gas, printing waste gas, chemical waste gas, and copper clad plate waste gas.

本文由沸石轉輪+CO友情奉獻.更多有關的知識請點擊:http://www.azsolar.cc真誠的態(tài)度.為您提供為全面的服務.更多有關的知識我們將會陸續(xù)向大家奉獻.敬請期待.

This article is dedicated by zeolite wheel+CO friendship. For more information, please click: http://www.azsolar.cc Sincere attitude. We will provide you with comprehensive service. We will gradually contribute more relevant knowledge to everyone. Stay tuned

截屏,微信識別二維碼